-

+86-13502131345

+86-13502131345

Qp960 8lane Liquid/Paste Stick Packer Stainless Steel 304 Machine Construction Technical Specifications: Model QP-8L Product Liquid Paste Dose Weight 10-50G Dosing piston Pump Accuracy +-1% Stick Shape Stick, Flat Cut Stick Width Customer-build Stick Length 40-190mm Speed 25-40strokes/min No of lane 8 lanes Capacity 200-320 sticks/min Seal type Fin Seal Packing Film Laminated Film Air … Continue reading Multi lane packing machine

|

Model |

QP-8L |

|

Product |

Liquid Paste |

|

Dose Weight |

10-50G |

|

Dosing |

piston Pump |

|

Accuracy |

+-1% |

|

Stick Shape |

Stick, Flat Cut |

|

Stick Width |

Customer-build |

|

Stick Length |

40-190mm |

|

Speed |

25-40strokes/min |

|

No of lane |

8 lanes |

|

Capacity |

200-320 sticks/min |

|

Seal type |

Fin Seal |

|

Packing Film |

Laminated Film |

|

Air Pressure |

0.6-0.8Mpa |

|

Air Consumption |

0.4m3/min |

|

Voltage |

220V,50HZ, 1Phase |

|

Power |

6.0Kw |

|

G.W. |

1500kg |

|

Dimension(L×W×H) |

1800×1200×2200mm |

Touch screen Kinco, Taiwan

PLC Omron, Japan

Cylinder Airtac, Taiwan

Servo Motor Schneider, Japan

Temperature controller Omron, Japan

Frequency Schneider, Germany

Photocell atonics, Taiwan

|

Hopper with liquid level control

|

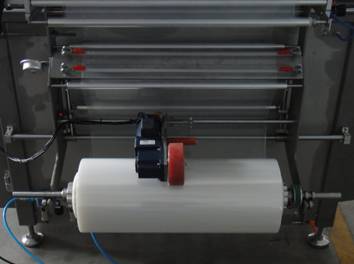

Roll Film Feeding

|

|

Hibar Pump

|

Roll Film Direction Reject

|

|

Vertical Seal

|

Easy Roll Film Change Connection:

|

|

Horizontal Seal

|

Ribbon Printer for date:

|

|

Dual Pneumatic Cylinder For Solid Seal

|

8Lanes Vertical Cut:

|

|

Servo Motor Film Driven, Easy to adjust stick length

|

Photocell Track:

|

|

Temperature Control

|

Static eliminate

|

|

Open Door Protect Stop Function

|

Openable electronic control cabinet

|

|

Unwinding Arrangement

|

: Maximum film width – 848mm : Maximum reel diameter- 300mm : Film control through electronic web edge controller. : Motorized pulling at unwinding section. : Aluminum dancing rollers. : Easy reel bob & shaft setting to place new roll |

|

Filling System

|

: Piston filling system : Nos. of filling tracks- 8 : 30kg hopper AISI SS- 316L : Filling accuracy +/- 0.1% : Filling Plate SS- 316 : Individual track fill weight adjustment through servo |

|

Sealing Unit

|

: Mechanical cam driven : Sealer frame fabricated MS : Sealer – SS-410 : Spring loaded equal pressure setting. : Individual heater. : Adjustable pouch width arrangement. : LM guided movement mechanism. : 90 degree outer jaw opening |

|

Pulling Unit

|

: Pull roller shaft – SS- 304 : Pouch pull roller- Polyurethane. : Pulling the laminates being pulled by Servo motor : Plain Circular cutter to make two strip of pouch individual. : Provision for circular cutter with notch to collect strip of pouch in met form. |

|

Film Turn Bar Unit |

: Aluminum rollers. : Film center aligning knobs. : The laminate is coming thru web aligner and it being cut by center slitter and distribute in two equal parts. |